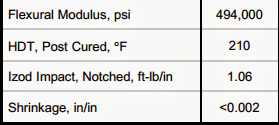

Another disappointing weekend on the books for Infusion testing.

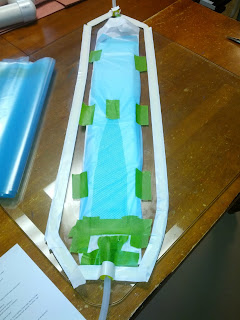

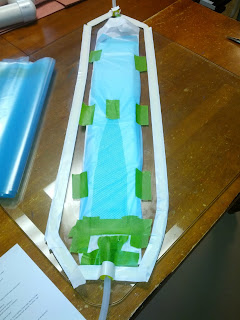

I tried to duplicate the original layer test and attempted to make a "V" shape with the Resin Distribution media to force it through the thick layers of fabric before taking a shortcut. This seemed to work, but I cut the distribution media too far away from the vacuum port and the infusion stalled after an hour (moving only 7cm past the tip of the distribution media).

|

| "V"-shaped distribution media, cut too short |

Once the infusion stalled, I just stopped it and removed all the materials into the garbage.

No sense in letting it hang around and take up space.

The next infusion was a perforated piece of foam (no pictures) to simulate a double-sided bulkhead infusion.

Things were going well until I clamped down too hard on the resin inlet line trying to throttle the flow and cut the tubing. Then I tried putting on another clamp which weighed down the inlet port causing it to pop out of the tacky tape seal. That was because I was using the smaller diameter PE line instead of 1/2".

Then to finish off the disaster, I tried replacing the line with a 1/2" tubing and ended up ripping the bag.

A "not so funny" comedy of errors - so I just sat there with a stupid look on my face and decided it was time to clean up for the day.

The next day, I decided no more lay-ups and infusions in the same day!

Layups will be on one day - Infusions will be the next.

It's just too much for me at this stage, plus there is a whole different set of tools and supplies required for each operation. Leading to clutter and chaos.

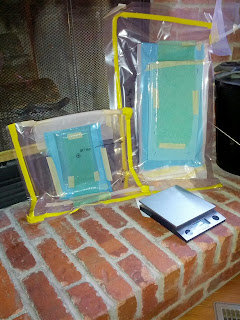

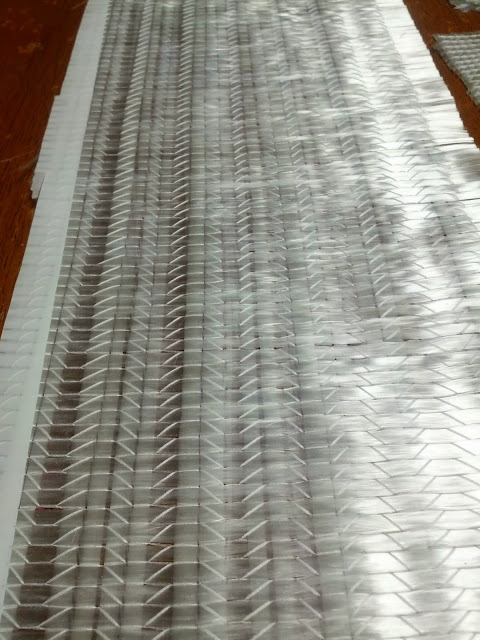

Changing gears, I spent the next day working on the beam mold fabric layup.

Still some more layers to do yet.

|

| Two-Piece Patterns for Beam Recess |

|

| Some Carbon layers |

|

| More Carbon Uni |

|

| Still some more glass to layup |

I also built a valve assembly to regulate the resin flow.

I realize you can purchase disposable valves, but those prices can add up and I'm curious to see if a "real" valve can be cleaned out and reused since the resin is relatively thin and will nearly drain out completely.

I'm thinking a vinegar bath with some Q-Tips will do the trick..?

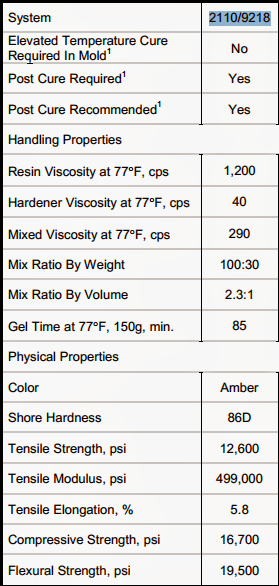

Another problem I ran into was inadequate Resin supply mixture. The spreadsheet I developed to calculate the required amount needs some modification to add more for the disposable layers. An easy fix, but maybe not even required in the long run? I've found an

epoxy distribution machine that has the option to add an inline static mixing block. The static mixers are expensive, but the idea of simply pumping out what is needed/as needed along with less air trapped into the mix and a continuous fresh supply being fed into the part might well end up off-setting those other costs.

Next weekend (depending on supplies remaining) I'll try another layer stack and bulkhead infusion test.

.jpg)