(2/15/2023 - Thank You Arno for prodding me to update this Blog)

======================

Hello Internet,

It's been almost five years since my last post....

Sadly, a divorce situation came along and derailed a lot of progress setting me back quite a bit.

:(

When the dust finally settled, I was forced to sell the house we had purchased and move into a shared apartment with two of my daughters. There was nowhere to store the float I had built, so it was cut into pieces and most of it was thrown away. The rest of my tools were cleaned, packed away and moved into storage along with a dozen sheets of foam, the beam molds, float patterns, a few bolts of fabric, the vacuum pump and some assorted beam parts.

Locking the door to that storage shed and walking away felt like "The End" all over again....

What would I do? What was the next step...?

I spent the next year working through different decisions trying to figure out if there was any possible way to restart the build. During this time I started taking dance lessons, making new friends, traveling here and there and just continued working on myself and trying to become a better person.

Eventually, enough time passed that I felt like it was time to move on.

I needed to make some choices, refocus on my life and start moving things in the right direction.

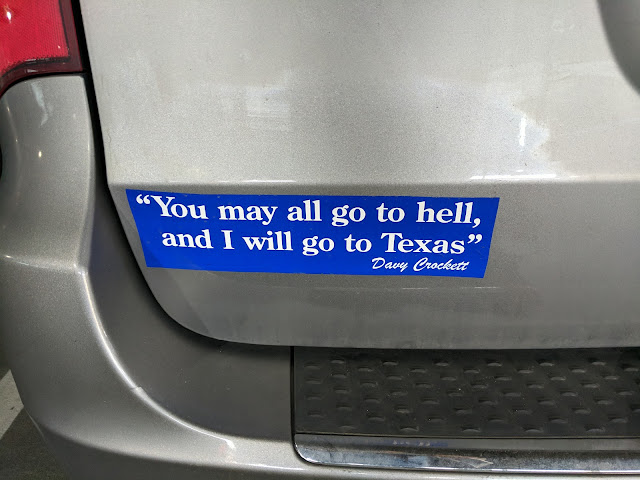

I figured the best thing to do would be to buy some land, build a shop, pick up a small camper and live out of that while building the boat. I later decided to build a tiny apartment (250sqft) instead of a camper since the resale value would be much better in the future. I spent the next 18 months looking for and visiting various properties north of Dallas, TX.

I didn't think I was asking for much...

I wanted less than five acres in a good area, easy access to Hwy 75, city water, no HOA, the ability to build a shop WITHOUT having to build a house, good neighbors, a great view, High Speed Internet, the option to build a house later on and a small pond would be SUPER nice.

Well, apparently that's A LOT to ask for!!!

I had just about changed my search options to townhouses and go a different direction in life when a "coming soon" listing popped up in my email. I took a look at the location via Google Maps (there wasn't even an address yet) and drove out to see it.

It was PERFECT!!

I called my Realtor and submitted an offer the next morning.

We settled on a price and closed within 30 days.

:)

The next two years involved getting an address, building a shop (I contracted the slab and steel shell), running all the utilities, installing a septic system (big enough for a 4-bdrm/3-bath house PLUS the shop), insulating the shop, building out a small apartment, installing two HVAC systems, cutting in a driveway and building a small patio.

All while dealing with a pandemic and all the chaos that brought along with it!

I moved into the apartment in August of 2021 (it was about 60% complete at the time).

Since then, I've been busy finishing things up here and there, holding down two jobs and getting my financial life back in order.

I plan on starting with the beams since I have most of the materials and parts already made for them except for a bolt of 17oz double-bias (45/45) fiberglass and maybe 15 gallons of epoxy. The plan is to have all four beams completed by EOY, which "should" allow time needed for trips and other projects planned around here.

Stay tuned - more information coming...

=========================

Here is a link to almost 400 photos of the shop build.